POLYURETHANE (PU) SANDWICH PANELS

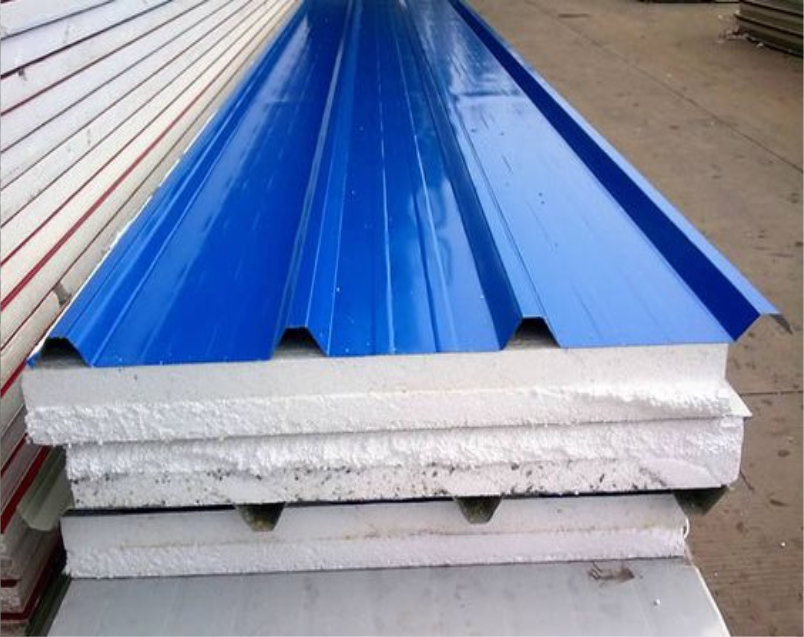

Polyurethane (PU) Insulated sandwich panel is a composite building material. It is made up of a rigid core sandwiched between two metal sheets. Rigid polyurethane (PU) foam is the internationally recognized best construction material where heat insulation properties coupled with strength are required, like in Pre-engineered buildings, warehouses and cold-chain solutions.

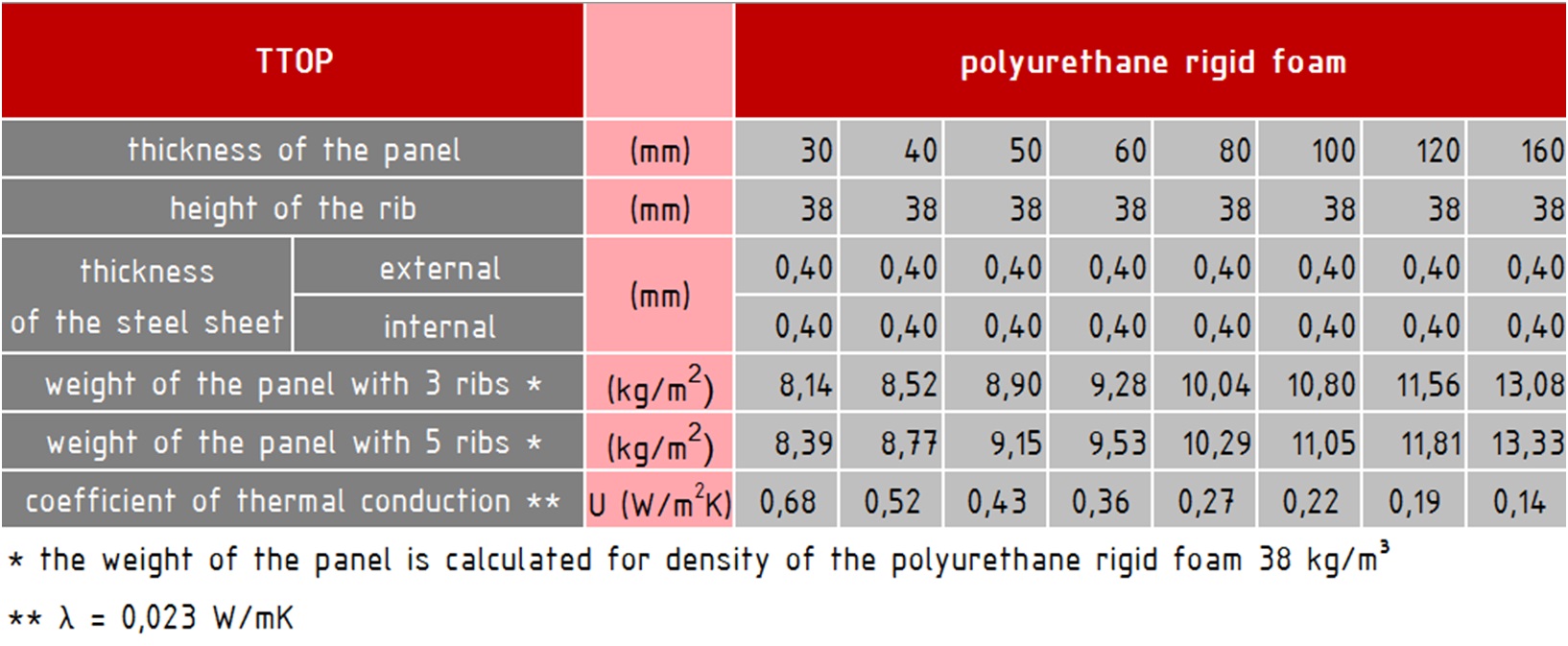

PU panel has low thermal conductivity (R-value). R-value is an important measure of resistance to heat flow through a given thickness of material. R-value figures of PU panels are given in the table (The lower the better).

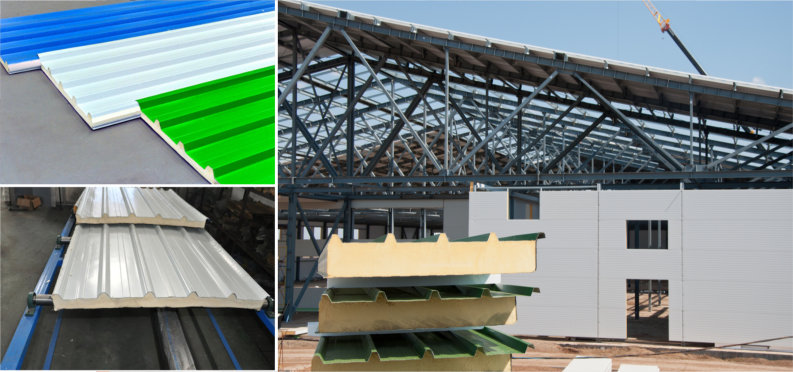

Sandwich Panels are typical single piece, modular, factory engineered units comprising of two metal faces sandwiching a highly efficient insulating materials like Polyurethane or Polystyrene. These are high performance building panels used for residential, commercial as well as industrial buildings. EKN Cooling System manufacturing wide range of Water Proof, Tamper Proof, Corrosion Resistant, Durable Coating and trustworthy Polyurethane (PU) & Expanded Polystyrene (EPS) Sandwich Panels, Cold Storage Room, Modular Portable Cabin, Pre Engineering Building and Industrial Fabrications both in Mild Steel & Food Grade Stainless Steel.

(K⋅m2/W) is the R-value, which is inverse of U in the table.

R-value is one of four other key parameters that determine the effectiveness of an insulation material, which are high heat resistance, good load bearing and high bending strength. PU panel is non-absorbent, anti-rot and non-rusting. It’s not moth eaten and rat bitten and has good fire resistance. Low thermal conductivity of PU panelsalso greatly reduces the peripheral thicknesses of the building wall-panel and roof-panel structures, thus effectively increasing the covered area of the building and savings in energy costs.

We at EKN have a range of core thicknesses, support finishing and panel joints to choose from. The panels can be assembled by vertical or horizontal disposition, and are suitable both for interior and exterior applications.Metallic sheet is placed on a specially-designed mold, and with the aid of a spraying device, polyurethane foaming agent is sprayed on the sheet. Computer control is used to make the foam formed between metal sheets, so that complete color steel sandwich PU panel with three layers is formed at one time.

| Available Total Thickness Of Panel | 40mm ~ 180mm |

| Prepainted GI Sheet Thickness (Each side) | 0.40mm ~ 0.8mm |

| Colours | Any |

| Maximum Single Production Length | 15 meters |

| Available Density | 38 Kg/m³ ~ 45 Kg/m³ |

| Type of Panels | Wall and Roof |

| Inter-Locking Arrangement | Male-Female, Cam Locks |